MTS5-300 Test Stand with DFS Set 5N-1,000N

Price range: $610.00 through $830.00

MTS5-300 Hand Wheel Test Stand with DFS Set

Available in capacities from 5 N to 1,000 N

(Please select a capacity from the dropdown list)

Elevate your testing precision with the MTS5-300 Test Stand, an engineered solution designed to pair with our DFS model force gauges. Whether you choose the stand-only option or the complete set, including the force gauge, the MTS5-300 delivers unparalleled performance and versatility to meet your testing needs.

Key Features:

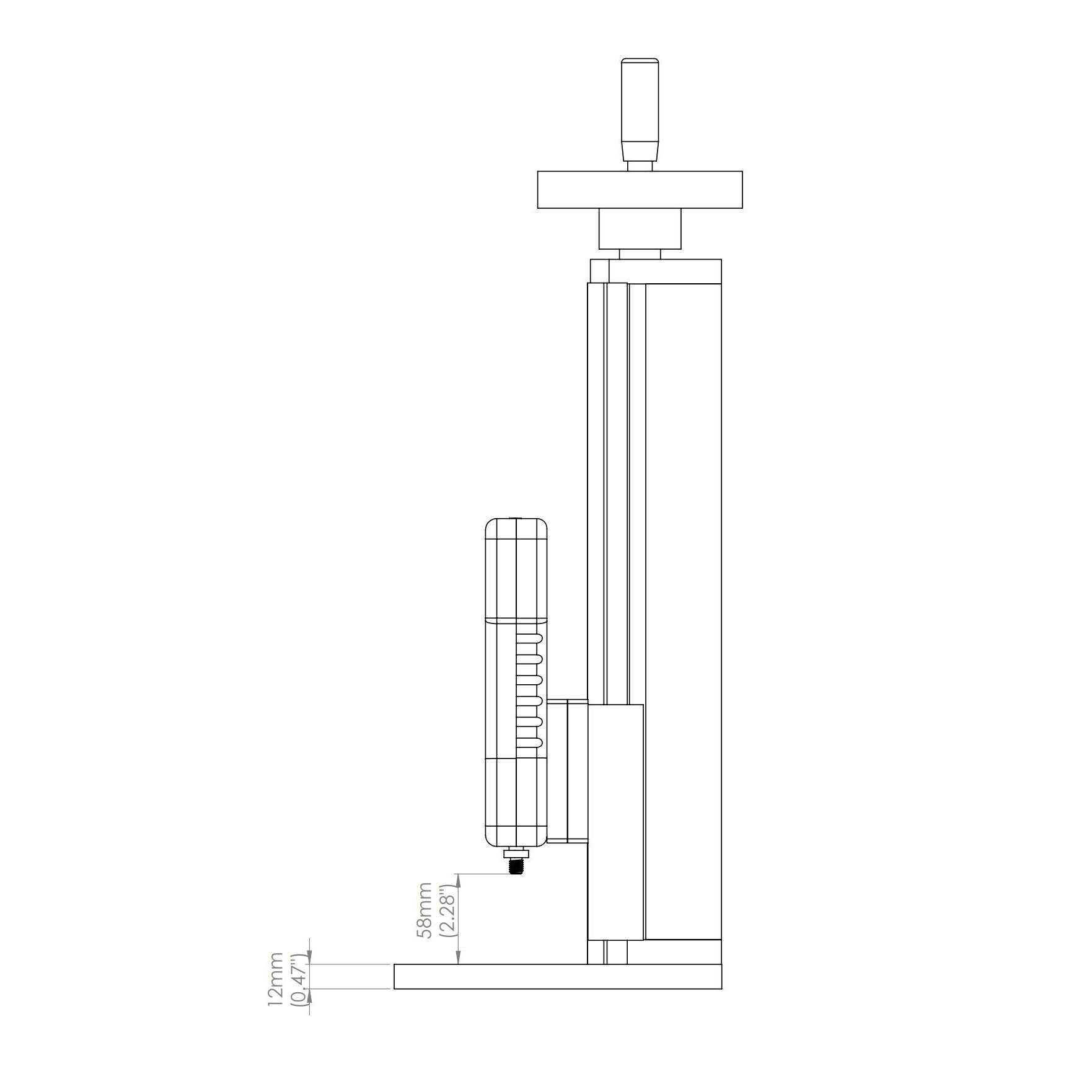

- Driven by a CNC grade 16 mm (0.63 in) ball screw and ball nut, the MTS5-300 ensures smooth and precise positioning for accurate force measurements

- Versatile functionality allows the test stand to operate in tension and compression and is adaptable for a wide range of testing applications

- Solid stainless steel construction, paired with a serrated hand wheel, ensures durability and reliability even in demanding testing environments

- The set includes stainless steel accessories consisting of seven pieces, along with two gauge mounting plates and screws, which offer enhanced convenience and adaptability for various testing setups (Grips and clamps are not included)

- The DFS model force gauge, included in the complete set, boasts peak/max hold and tracking modes for both tension and compression testing

- Each force gauge comes with a factory-issued calibration certificate that guarantees the accuracy and reliability of your measurements

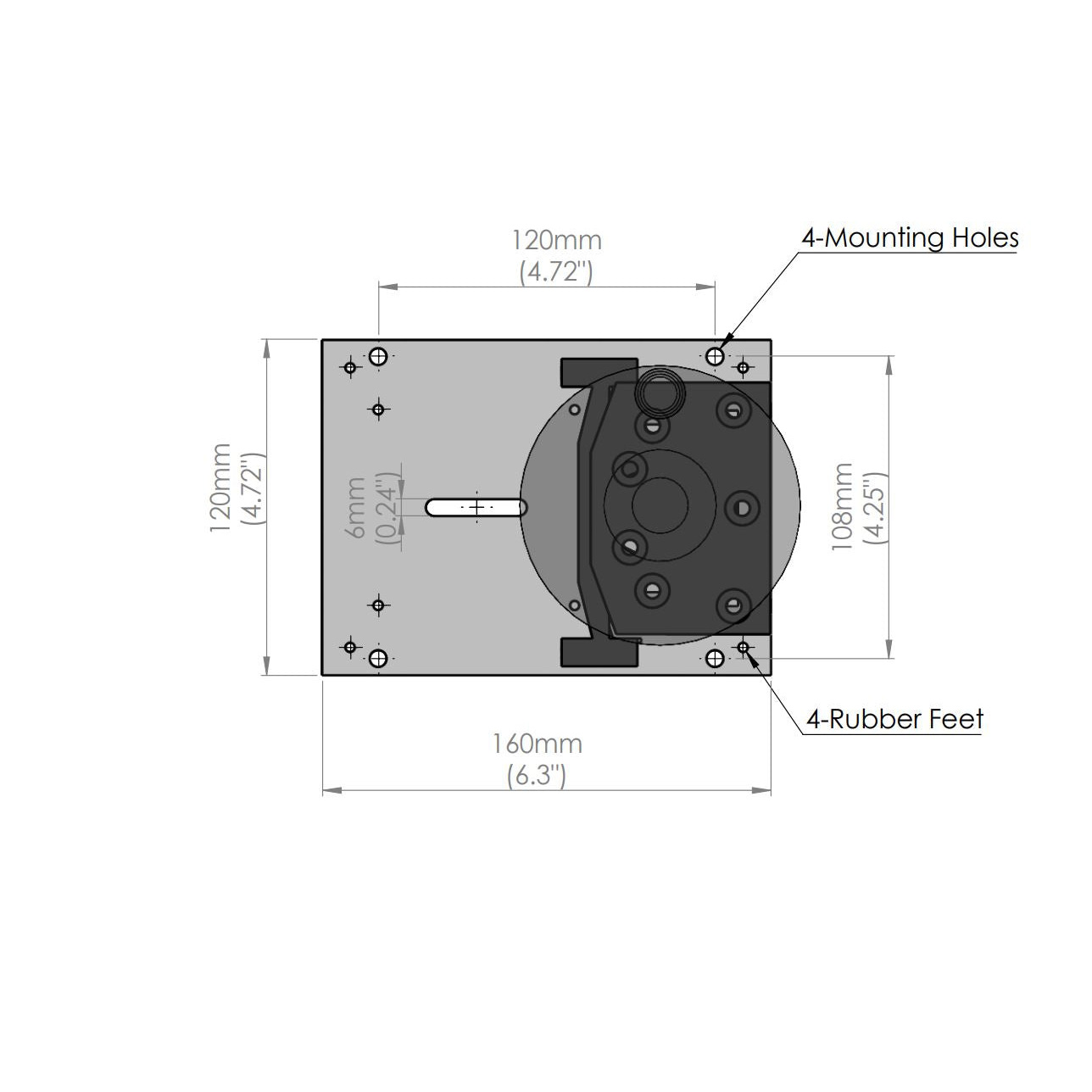

Experience precise force control with a 5 mm (1/5 in) displacement for each turn of the wheel, allowing for effortless application of maximum force with minimal torque required. The low friction ball nut and ball screw system ensures smooth operation and performance, while the load mounting plate at the bottom features a 6 mm (0.24 in) slot for easy mounting of grips or clamps.

For more details on the force gauge please visit the DFS Series product page.

The MTS5-300 enhances testing for various applications including but no limited to:

- Material Testing: Assess the tensile or compressive strength of various materials, including metals, plastics, and rubber, with confidence and accuracy.

- Product Quality Control: Ensure product integrity and compliance with industry standards by conducting rigorous force tests on components, assemblies, and finished products.

- Research and Development: Facilitate innovation and advancement by conducting precise force measurements for research projects and product development initiatives.

Note: The MTS5-300 Test Stand provides tactile feedback during testing, thanks to its low friction design. When testing elastic spring materials, be aware that the hand wheel crank may turn by itself as the material returns to its original shape after force application.

Additional information

| Weight | N/A |

|---|---|

| Capacity | 1000N, 500N, 200N, 100N, 50N, 20N, 10N, 5N, Test Stand Only |

| Force | Tension and Compression |

| Stroke Length | 300 mm (11.8 in) |

| Certification | NIST traceable calibration certificate |

| Drive | CNC Grade 16 mm (0.63) ball screw |

| Material | Metal |